2 members contacted us to see if we would come on and enter a discussion on the issues with direct injection and the related issues. We do have a F150 EcoBoost 3.5 twin turbo. There are 2 other cans on the market that catch most of the oil mix as well, the SMC (Saiku Micchi), the ELite E2, and the Apex (a copy of the Elite E2). Routing and the use of checkvalves to prevent any boost pressure entering the crankcase are critical. As for the rest, most are only 10-30% effective so although they capture oil (even a beer can or mayonnaise jar will as well), they are letting most pass right through so they are little more than placebo's. Carb cert is in the future.

What one can do is a manual intake valve cleaning to restore the valve shape to original and see the improvement in power and smoothness. It is not difficult, it just takes time. Make sure all ports are taped off to avoid any debris from entering, and bring the one your cleaning up to TDC to make sure both valves are closed. Use compressed air and a shop vac to remove the debris as your cleaning. A die grinder or cordless drill with some long shaft brushes will allow you to get at all sides of the valves and intake port. When clean, blow debris clear and tape off and move to the next. Just take your time when removing and reinstalling the IM...the O-ring gaskets are reuseable many times, so only need to get the brush set. Amazon has many to choose from.

Well we don't know that necessarily. But what I DO know is that with two very modified vehicles I have use breather cans. Both have been driven to over 150,000 miles. And both were completely factory engines. Never had an issue. (Though I did change my oil at least every 3000 miles). I also can say I dropped my fair share of intercooler pipes and I never saw oil in the intake pipes with a breather can on mine. Other cars without them absolutely.

As far as emissions, well I live in PA and that part of the inspection is entirely visual. Just reconnect the rubber lines and you will always pass. Other states I don't know about.

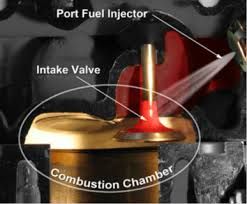

We also do know that those intake gasses and oil run hell on your valves and guides over time on a DI engine.

For me, at least, I think the lesser of two evils is common sense here.

On the other hand, with 40 years of direct experience in demanding high profile venues, if anyone is going to have a better solution to an impending problem it would be you. So I'm all ears!

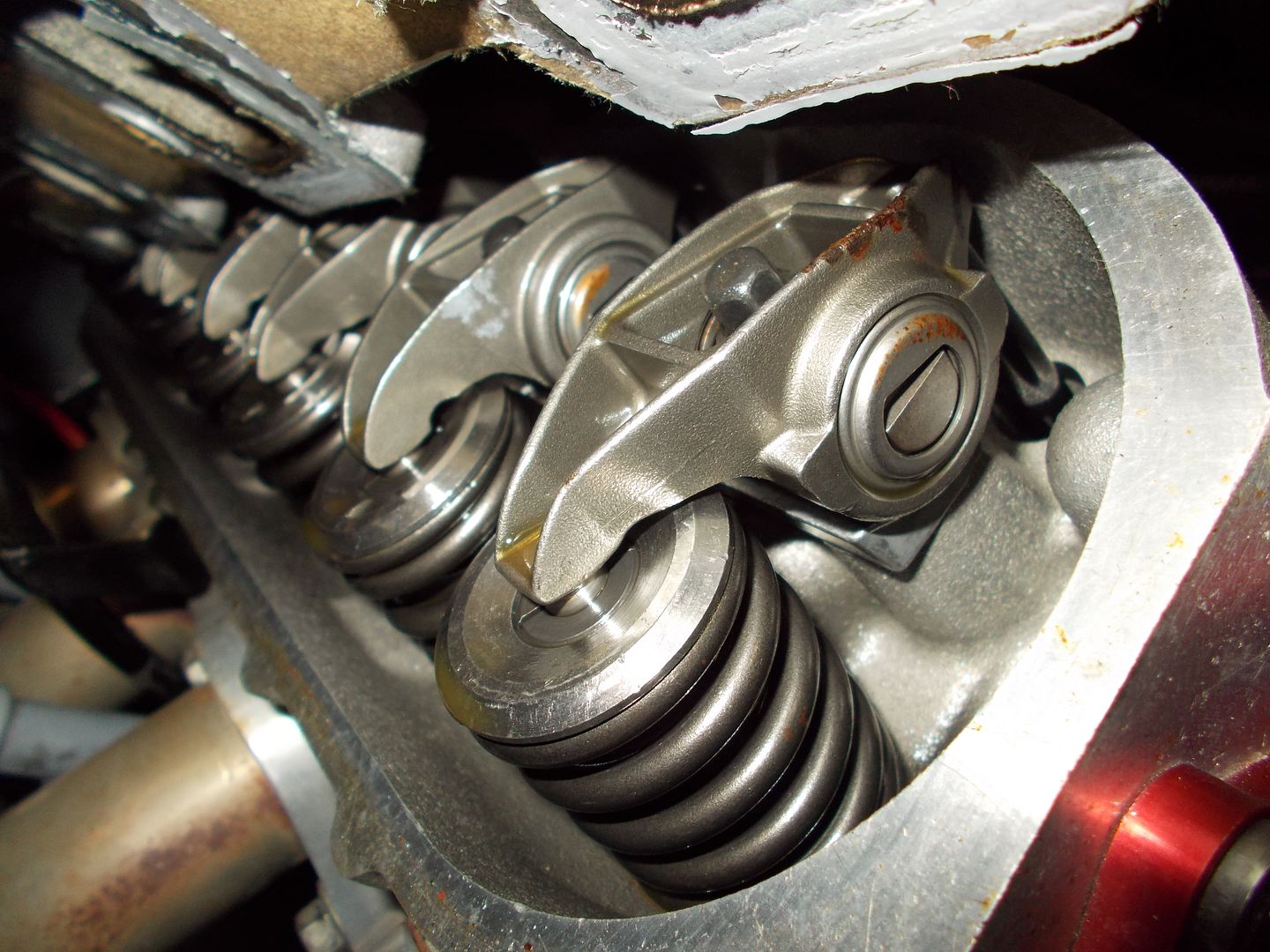

Your correct if you are changing oil often enough....but a simple BlackStone oil analysis will show the level of contaminates accumulating in the oil. I am referring to the actual wear on all moving parts over time. Most would not know the rate of wear w/out a tear down. When you do tear down, look closely at the bearings and journals. Those little "worm track" stains are the sulfuric acid attacking the bearing surface and the case hardened journal surface. Look on the valve train components....rocker arms with roller bearings (most modern engines or any after market) and you will see the corrosion attacking them as water and acid condense under the valve covers. This example is from only 6 months of breather alone:

The mild steel buckets are thin and when they are breached the needle bearings spill out. Always try to do the absolute best for any engine, race or street.

With all our race engines we run belt driven vacuum pumps to ensure immediate evacuation of all of this and also try to maintain 14-15" of vacuum to aid ring seal. This allows us to run a low tension ring as well for less resistance. We dont want ANY oil ingested and these engines have to repeat round after round as we win or lose far too often by 1/1000th of a second or less:

We constantly have DI engines in here for re-ring and/or intake valve/guide issues from this:

This is what you will find is evacuated and caught vs just venting:

![Image]()

Bottom layer settles to be mainly sulfuric acid and water, then unburnt fuel and water emulsified, then water and oil emulsified, and the very top oil alone settles out. Not what you want in the oil. We always have examples of engines that go miles against all odds, the occasional car comes in with no oil change for 50k miles and still runs fine not burning oil, etc. and the time a guys wife got in his new truck that he was doing the 1st change at 1000 miles and starts it up and drives off with no oil in it (the drain pan still under the truck), drives 20 miles to town, shops and drives back home clacking and rattling like crazy. He fills the oil and gradually all lifters free up and get quiet....last I talked to him he had close to 200k miles on it but the body was rusting off (WI). Aside from burning a qt every 2k miles, he says it ran fine. So, as a Professional race team owner, we look at every way possible to extend the life of not only the race engines that may be $20-$45k each, but the tow vehicles as well. So yes, you may very well get long life out of the engine, but it could have been better.

And have developed several FI systems for the new DI engines:

![Image]()

So, to understand crankcase evacuation, all engines need a filtered (and if MAF equipped a MAF metered source) fresh, or cleanside source that brings in clean air to make up for the foul/dirty air pulled out. This also aids in "flushing" these damaging compounds out. This clean air travels through the crankcase flushing the damaging foul vapors out the opposite side of the crankcase. Similar to a smoke filled room that has a vent filling it with smoke. Open on window and you relieve pressure and some smoke escapes, but until you can open a window on the opposite end, and have a fan pulling (evacuating) that smoke out, the room can never clear. The crankcase is similar. Most only think in terms of relieving pressure and are not aware of the damaging combustion by-products constantly entering as blow-by. They must be removed before they can settle and mix with the oil. And yes, a motor may still run and seem OK, but the increased wear does occur and can be seen when you tear down.

Good dialog here!! Keep it coming!

![Image]()